Table Of Content

This can help lower the car's centre of gravity to improve stability and also allows the team to fine-tune the weight distribution of the car to suit individual circuits. In fact, the complex nature of carbon fibre manufacture has allowed teams to bend the rules – quite literally – by creating wings that are weaker in certain areas and can flex under load, passing static load tests but moving out on track. In 2008, the FIA further strengthened its cost-cutting measures by stating that gearboxes are to last for 4 Grand Prix weekends, in addition to the 2 race weekend engine rule. Furthermore, all teams were required to use a standardised ECU supplied by MES (McLaren Electronic Systems) made in conjunction with Microsoft. These ECUs have placed restrictions on the use of electronic driver aids such as traction control, launch control, and engine braking and are tagged to prevent modification.

Is Haas destined for a miserable 2024 F1 season? Our verdict

The F1 cars for the 2009 season came under much questioning due to the design of the rear diffusers of the Williams, Toyota and the Brawn GP cars raced by Jenson Button and Rubens Barrichello, dubbed double diffusers. Appeals from many of the teams were heard by the FIA, which met in Paris, before the 2009 Chinese Grand Prix, and the use of such diffusers was declared as legal. Brawn GP boss Ross Brawn claimed the double diffuser design as "an innovative approach of an existing idea". Another controversy of the 2010 and 2011 seasons was the front wing of the Red Bull cars. Footage from high-speed sections of circuits showed the Red Bull front wing bending on the outsides subsequently creating greater downforce.

Mercedes battling “fundamental” issue with new W15 F1 design - Motorsport.com

Mercedes battling “fundamental” issue with new W15 F1 design.

Posted: Mon, 11 Mar 2024 07:00:00 GMT [source]

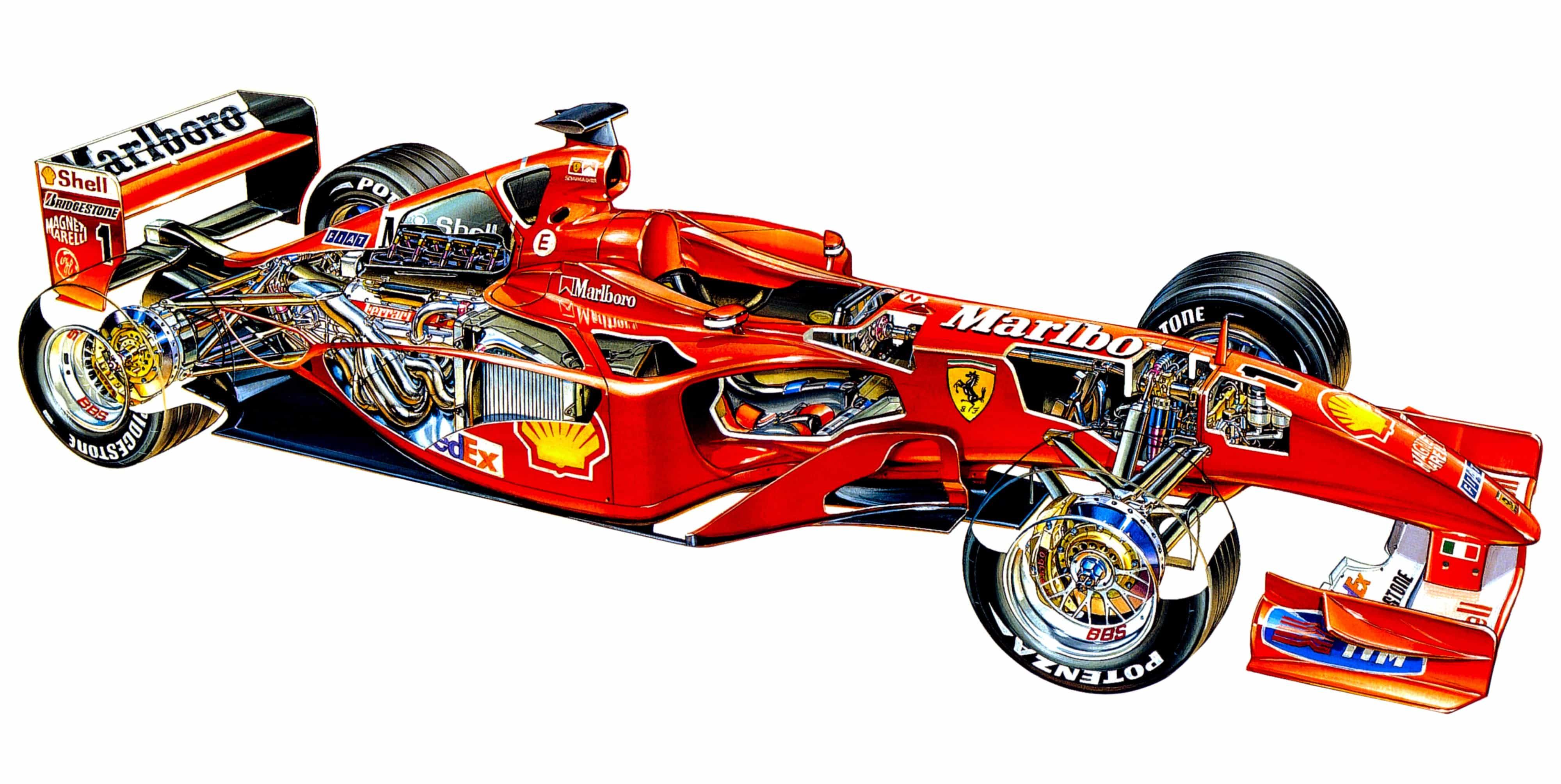

Engines

“We used to go down the route of a few big updates each season, each one quite discrete. If we’ve found something that improves the car, we want to get it to track as quickly as possible. From what we can see, there is also a well-crafted aero shape in that undercut that builds on last year’s design.

Inside the Race to Build America’s EV Charging Network

Mercedes, on the other hand, has focused more on ‘making legal’ the endplate that was introduced last year in Miami now that those rule tweaks have taken place. The endplate can be cut more to favour the outwash as in 2022, but Mercedes has studied the shape of the external flaps that throw the flow outwards with a painstaking work of micro-aerodynamics. The new regulations implement a series of design changes intended to lessen the impact of this dirty air in order to promote closer racing and easier passing.

How are teams solving this problem?

The acceleration figure is usually 1.45 g (14.2 m/s2) up to 200 km/h (124 mph), which means the driver is pushed by the seat with a force whose acceleration is 1.45 times that of Earth's gravity. The sidepods play an important part in packaging the car as tightly as possible, housing the radiators and manifolds compactly, minimising drag. The driver with DRS has a lot to consider, such as braking point and positioning the car to make sure they are well-placed to leave the corner ahead of the leading driver.

Audi's first F1 driver has earned his unlikely redemption

F1 brakes are 278 mm (10.9 in) in diameter and a maximum of 32 mm (1.3 in) thick. The carbon/carbon brake pads are actuated by 6-piston opposed callipers provided by Akebono, AP Racing or Brembo. The regulations limit the modulus of the calliper material to 80 GPa in order to prevent teams using exotic, high specific stiffness materials, for example, beryllium. Titanium pistons save weight, and also have a low thermal conductivity, reducing the heat flow into the brake fluid.

F1 Quiz: Every driver who took part in testing 10 years ago

But exactly how fast they are is perhaps not something people dwell on too often. Whilst the Haas render showed just a single element, there's the possibility for teams to use up to two elements. This can not only have an impact on the wheelbase and positioning of other structures and elements, but it can also influence the design of the coke bottle region. At the rear of the car, there will undoubtedly be some decisions to be made over the design of the transmission casing. One area where teams did things very differently in the past was with car length. The elephant in the room, however, is the looming 2021 technical regulation change.

Alpine, for example, runs 16 machines to process all these parts and replaces them every three years. Carbon fibre parts begin life with a pattern, typically made out of epoxy using five-axis milling machines that use CAD data to cut to an accuracy of 0.05mm. The patterns are then used to manufacture a female mould out of carbon fibre, which is then used to make the final part. Most model parts are now made with rapid prototyping and 3D printing, with the wings made of metal. In the tunnel, the car is bolted to a central spine and a fan blows air over it with a belt under it running at a matching speed. Different sub-groups take care of different areas or aspects of the car – such as transmission, electronics, mechanical design and aerodynamics, as well as composite design, which involves planning the way parts are manufactured.

Ferrari

In this, as in every season, there’s a point at which teams – even teams fighting tooth-and-nail for a title or a good final position in the constructors’ championship – will stop attempting to improve their car. They do it because the returns from improving the current car are outweighed by the need to devote time and energy to the next one. With no major technical changes for 2020, upgrades from 2019 continued to come late into the season because any goodness located for the current car was likely to be transferable to the new. “Behind that, there’s another stream of development that deals with bigger changes,” he added. “This will be things we’ve seen in the wind tunnel that look like they’ll bring performance – but they perhaps need to be combined with something else.

All of these changes will undoubtedly have an impact on the height of the wake being generated, with the volute-shaped endplates introduced in 2022 taking things a step further than before in order to redefine the shape of the wake created. Increasing the rear wing's height is not the only change though, as the width of the upper section of the assembly is increased to 1230mm, rather than 950mm, resulting in a design that encroaches on the tyre's footprint below. The design of the front wing has been simplified once more, with the neutral central section of the mainplane done away with in order to eradicate the Y250 vortex that had become a powerful tool used by the teams since its introduction in 2009. The wing will also sit 25mm higher than it did before, mounted 100mm above the ground, rather than 75mm. The wholesale change in how the front-end aerodynamics connect to those in the middle of the car might see teams make different choices than they have in the past in this respect. It's something that we've seen teams correct during the course of a season too, with the Lotus E21 being the most recent recipient of such an alteration.

The 2021 season was one of the all-time greats in Formula 1 history, with Max Verstappen in the Red Bull RB16B dicing with Lewis Hamilton all season long in the Mercedes W12. We’re excited to get back racing in Baku and continue that cycle of learning and development. Ferrari might not be facing any problems now, and they certainly look to have started the year with a quick car. An F1 car has to work in a number of different conditions, and it is never a perfect scenario. The moveable section can be up to 960mm wide and, like its predecessor, have an 85mm opening when deployed. The overall width of the wing also remains at 2000mm, but only by virtue of the dive planes mounted on the outside of the endplate, which make up the final 25mm each side.

Not just one of Newey’s most successful cars, but one of Formula 1’s most successful cars, which powered Damon Hill to title success come the end of the season. The FW15C had all the so-called ‘driver aids’ exhibited on its predecessor, as well as a yellow ‘push-to-pass’ button, which would lower the car through the active suspension and enable it to increase its top speed through having less drag. Aston Martin team owner Lawrence Stroll in fact dubbed Red Bull’s chief technical officer a “unicorn” for his unique achievements in Formula 1, which have seen him behind car designs which have now taken 25 – yes, twenty-five – Drivers’ and Constructors’ titles.

This would have cost downforce at the front of the car, so they also made the front wings 20cm wider to make up for that. The packaging of a pull rod suspension within the chassis also results in a small Centre of Gravity improvement. However, it can make life a little more difficult for the mechanics when preparing the car or making setup changes, owing to reduced access.

As the diffuser opens up the airflow accelerates further, creating an area of lowest pressure underneath the floor. Airflow is accelerated under the floor where it creates a lower pressure area, thus generating downforce as the higher-pressure air on top of the car pushes it downwards. This airflow can also be used around the edges of the floor, effectively providing a seal. The sidepods also open up at the rear in order to expel any hot air and teams often flare these openings up at circuits renowned for their high temperatures.

Well, as the teams develop through the season, putting on more and more downforce at the back of the car, Ferrari might struggle to balance it out at the front. If so, that would give them a car hamstrung with understeer which just won't turn into the corners. In addition, the vortices - little tornadoes of spinning air - which are generated at the end-plate and which are so crucial to a car's overall performance can be drawn inside the tyre to help control the wake. Because the rules mean we're pretty much stuck with a big flat plate, with very little curvature to help the air, all you can do is reduce the amount of speeding up and slowing down the air at the surface has to do - by 'backing-out' the tips. If the aerodynamics don't push down enough on the front, the car won't turn into the corner.

No comments:

Post a Comment